Process simulation gives confidence that a project will achieve the desired outcome and should be the first step for any project or can demonstrate the performance capabilities of an existing system. It is a crucial step for sizing equipment or directing a vendor to size and quote equipment as requested. Process simulation can also support finding solutions to existing Operations problems from pipe flow issues to equipment performance issues. Sabatini Engineering LLC uses the following process simulation software:

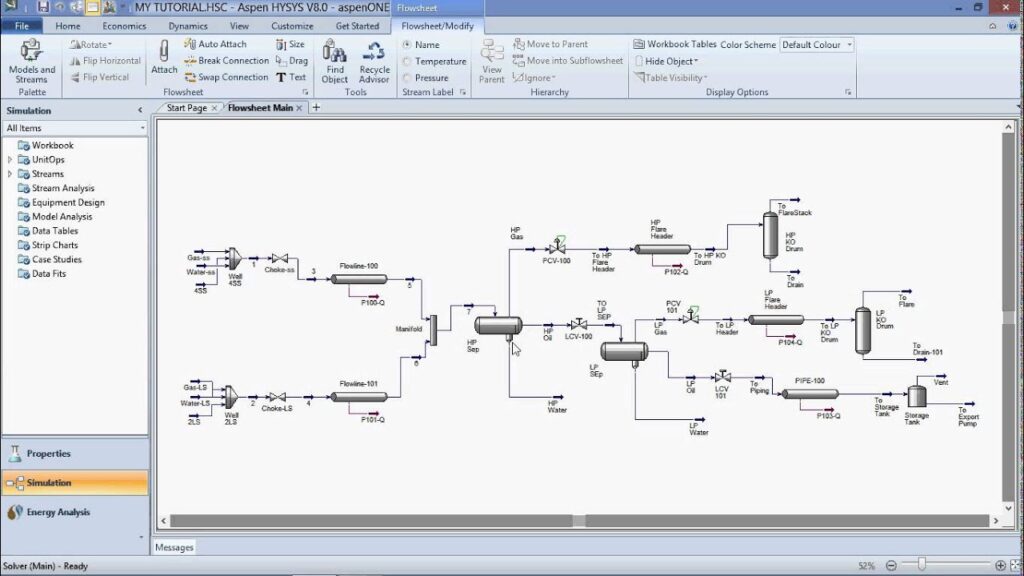

HYSYS – Steady State

HYSYS by Aspentech is the most widely accepted process simulation software for fluid processing facilities. Most basically, HYSYS when run in steady state mode provides a heat and material balance within specified boundaries for new or existing operations or even a specific piece of equipment. HYSYS steady state provides thermodynamic and fluid equilibrium calculations while maintaining conservation of mass and energy throughout the process. HYSYS steady state can also perform single phase and 2-phase pressure drop calculations through pipe and equipment as well as provide relief valve sizing for single or 2-phase fluid relief.

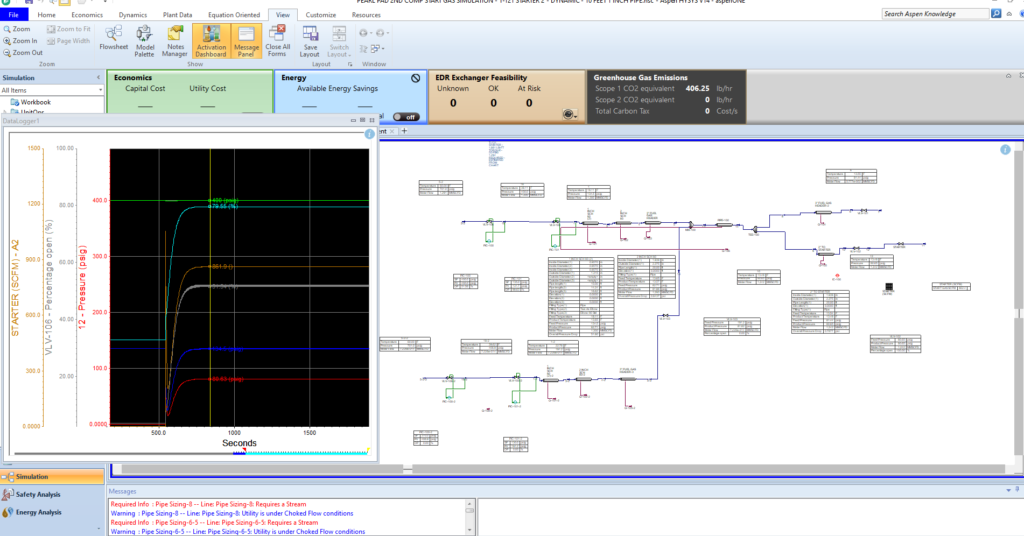

HYSYS – Dynamics

HYSYS Dynamics adds an additional dimension to a steady-state simulation, the fourth dimension of time! HYSYS Dynamics can simulate a fire to determine the peak relief requirements, help design an emergency blowdown system for a facility, or just show you what will happen if a certain valve is opened or closed by a certain amount. HYSYS Dynamics adds mass and energy accumulation to their steady state simulation to let you see what will happen to your system during startup, shutdown, or virtually any sort of upset to the system.

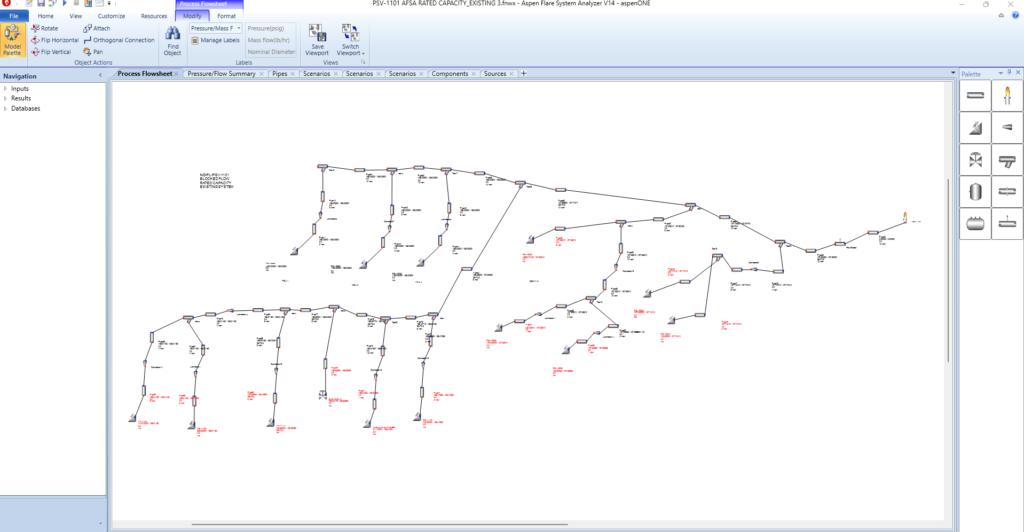

Aspen Flare System Analyzer (AFSA)

Aspen Flare System Analyzer (AFSA) specializes in relief system design. Stream data can be imported from HYSYS. AFSA incorporates gas, liquid, and 2-phase flow equilibrium and pressure drop calculations and unlike HYSYS, is designed for high velocity gas flow pressure drop calculations like those encountered during relief or blowdown of gas to atmosphere. AFSA is an integral part of any relief system design or audit performed by Sabatini Engineering LLC.

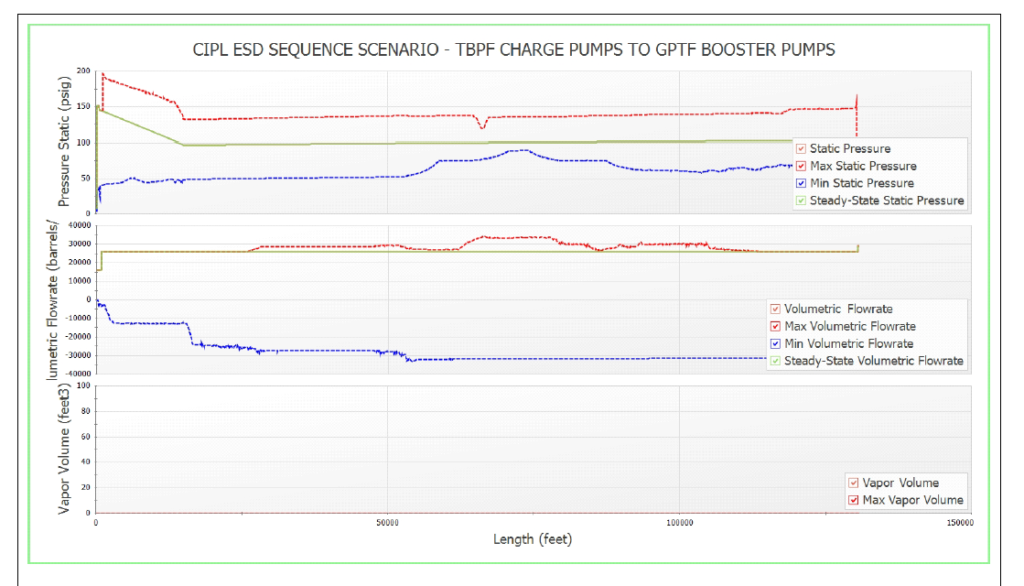

AFT Impulse – Surge Analysis Software

AFT Impulse models liquids pipeline flow in steady-state and dynamics mode use a PFD type interface. Reservoirs, tanks, valves, and pump curves can be built into the system and full steady-state process design can be simulated. Dynamics simulations for water hammer / pipeline surge can be performed to simulate any sort of change to the operating environment such as valve closure or pump shutdown. Graphs like the above can show maximum and minimum values for static pressure or a multitude of variables for anywhere in the pipeline. Animations and movies can be run to show the variables at any given time in the simulation such as the pressure wave generated when a valve is closed. Means to remediate pressure surges such as relief valves can also be modeled to see their effect in solving problems.